EMC product compliance testing: A comprehensive guide

EMC testing ensures that products do not emit too much electromagnetic radiation or do not experience adverse effects when exposed to electromagnetic fields. In this article, we will discuss EMC product compliance testing in detail.

Are you new to EMC product compliance testing? Well, becoming familiar with EMC testing can be quite challenging for beginners.

EMC testing is essential to assess the levels of electromagnetic radiation emitted from electronic products to identify any adverse effects on electronics in the surrounding area. It is required for all types of electronic products and the parts that make them. There are different EMC testing methods available.

So, if you want to learn what EMC testing is, how it can be done and the benefits of conducting it, you have landed in the right place.

Here, we have created this easy-to-understand guide to help you learn EMC product compliance testing in detail.

What is EMC testing?

An electromagnetic compatibility (EMC) test checks how well electrical products operate in their intended electromagnetic environment without causing intolerable electromagnetic disturbances.

Product EMC testing is conducted during the design, development, and production phases to ensure that the final product meets the relevant EMC standards.

Typically, many companies use EMC testing procedures in the development of new products, but it is also used to troubleshoot existing products to help find hidden problems.

What products must be tested for EMC compliance?

Several regulatory agencies have established EMC testing standards to reduce electromagnetic interference caused by electrical equipment. They help in preventing electronic products from interfering with each other.

Products requiring EMC testing are, for example:

- High-intensity lights

- LED displays

- Kitchen appliances

- AC adapters

- Electric motors

- Aerospace, military and defense devices

- Mobile phones

- Lithium batteries

- Health and medical devices or technologies

- Laptops

Problems related to EMC

EMC testing deals with several categories of problems, including:

- Emission

Emissions are electromagnetic disturbances emitted by electronic devices that may interfere with other devices in the same environment or affect their performance. Testing at this stage is generally known as Electromagnetic Interference (EMI).

2. Immunity/ Susceptibility

In an electromagnetic environment, immunity is the ability of the electronic device to function normally without getting affected by other electronic devices' emissions. It is basically defined as how resistant a device is.

There is an opposite relationship between immunity and susceptibility. Susceptibility is how vulnerable a device is to interference. In simple words, the more immune a device is to electromagnetic interference, the less susceptible it is.

EMC compatibility example

The following example illustrate the danger posed by electromagnetic emissions and how these affect victims:

During an airplane flight, passengers are asked to turn off their electronic devices: It shows the danger you may face when an announcer asks you to turn off your tablet, laptop, and mobile phone. Those devices' electromagnetic emissions can interfere with aircraft navigation systems that ensure a safe landing.

Types of EMC testing. EMC testing methods

There are two categories of EMC testing methods:

- EMC emission testing

- EMC immunity testing

1. Electromagnetic compatibility emissions

In this test, two types of EMC emission testing are examined: the conducted emission and the radiated emission.

E-field radiated emissions

Radiated emissions are any electromagnetic interference produced by electrical devices or systems. These emissions travel through the air either directly from devices or from their interconnected cables.

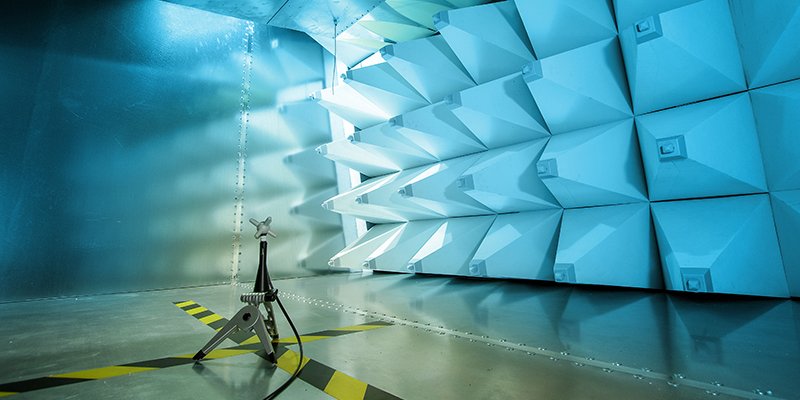

The testing labs use spectrum analyzers, measuring antennas, and electromagnetic interference receivers to measure radiated emissions.

H-field radiated emissions

The magnetic field (H-field) is measured with either an electromagnetic interference receiver, spectrum analyzer, or measuring antenna. Loop antennas are the most frequently used magnetic field antennas in EMC testing. Moreover, a specific antenna known as Van Veen Loop is used to measure the emissions of the electronic system or device on three different axes (X, Y, and Z).

Conducted emissions

Electronic devices and systems produce electromagnetic interferences (EMI) through their internal frequency generation, called conducted emissions. These interferences can be continuous or discontinuous and occur along cables, telecommunication ports, or power conductors.

Continuous emissions are emitted consistently at a certain frequency. They are measured using an EMI receiver located within a test chamber. The information is sent via the ISN (impedance stabilization network).

2. Electromagnetic compatibility immunity

EMC compliance testing for device immunity is either continuous or transient, depending on the electrical system or electronic device being tested.

Continuous EMC compliance Test

The techniques of EMC compliance testing for continuous immunity vary.

- Radiation immunity: It is a standard technique for EMC compliance testing. RF signal generators are used to generate electromagnetic fields to expose the product being tested for EMC compliance.

- Power-frequency magnetic field immunity: This test examines how well a device will work under a variable magnetic field produced by a coil of magnetism pulsing at 50 Hz. These tests are typically needed for products that are prone to magnetic fields.

- Conducted immunity: In this technique, the electromagnetic field created is connected to a product's signal, data source, or power source. It is an EMC compliance testing process for DC and AC ports or long signal cables over 30 meters.

Transient EMC compliance test

Many types of transient immunity tests are employed in EMC compliance testing:

- Electrostatic discharge: In this test, ESD pulses and coupling planes are subjected to the enclosure of the device at precisely defined levels.

- Surge test: When the signal cables extend more than 30 meters outside the building, surge testing must be done on the device's main port. It is normally done on AC ports or periodically on DC ports.

- Electrical fast transients and bursts: Tests of electrical fast transients and bursts are applied to AC power ports, DC ports, and signal cables longer than 3 meters. Fast transients are pulses with a high repetition frequency and amplitude that are usually stimulated by high-speed switching events.

- Pulsed magnetic field: A pulsed magnetic field is applied to the product undergoing EMC compliance testing after it has been placed inside a magnetic loop.

- Dips and variations: This type of EMC testing simulates power network faults. Power outages and significant fluctuations in load are typically the culprits. This technique is only applied to AC input ports.

Importance of EMC testing

Although specific requirements vary across countries and areas, EMC testing is still one of the legal requirements for the sale of electronic products in the majority of countries.

As an example, in European markets, all electronic products must bear the CE mark before they can be sold, and this can only happen if the maker complies with all relevant rules, including those concerning EMC. This is declared through the Declaration of Conformity (DoC), which is often included in a product's user manual. Providing new items without a DoC and EMC product compliance testing may be sanctioned by market surveillance authorities, resulting in heavy fines, product recalls, and even jail time.

Benefits of EMC testing

Testing your electronic equipment for EMC is important for many reasons, such as

- Reliability: Electronic products should be tested to ensure they will work as intended and accomplish their goals.

- Safety: The primary purpose of EMC testing is to ensure the security of users and operators of electronic devices and systems, such as circuits.

- Lower warranty costs: As the number of product failures is reduced, warranty costs are also reduced.

- Keeping up with government legislation: Conducting EMC testing makes complying with government regulations easier.

- Decreased Liability: Products and services that are not defective are less likely to cause lawsuits.

Final verdict

EMC testing procedures of electronic devices are a necessary part of the production process. A device cannot be assumed to be electromagnetically compatible if it has not been electromagnetically tested.

An EMC compliance test must be performed to ensure your device is compliant with EMC regulations. Without testing, it is usually impossible to tell how much electromagnetic radiation your device emits or how far it exceeds the legal limit. To find a suitable EMC testing lab, one easy way is to submit a free request using the testxchange online platform.