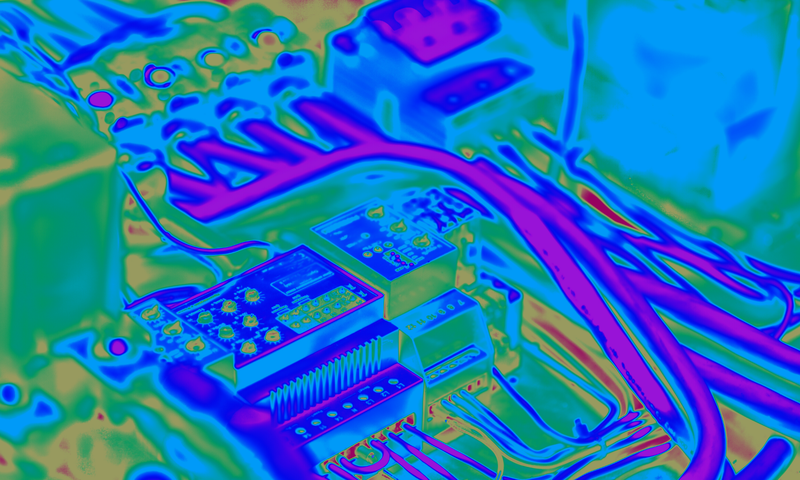

Thermal analysis

What is thermal analysis?

Thermal analysis is a generic term for specific examination methods for material characterisation. In this process, the chemical and physical properties of materials are determined as a function of temperature (cf. DIN 51005). These include, for example, weight loss, dimensional changes, heat flows or mechanical properties. Possible measured variables include crystallisation, melting, glass transition, oxidation, cross-linking, evaporation, decomposition, and thermal expansion coefficient. The thermal analysis provides a wide range of information about the composition of a substance mixture, its stability, processing, molecular structure, and chemical mobility. In the context of damage analysis, thermal analyses can also provide information about the relevant mechanism or the cause of the damage.

A sub-area of the investigation methods of thermal analysis is dynamic thermal analysis. A substance is alternately heated up and cooled down again in this process, and the temperature of the substance is continuously documented. Possible procedures for dynamic thermal analyses are thermogravimetry (TG), dynamic differential scanning calorimetry (DSC), differential thermal analysis (DTA) and emission gas thermal analysis (EGA).

For example, with the help of DTA, energetic processes in products and materials can be determined. This involves comparing the temperatures of the sample and the reference substance to document phase transitions. This allows conclusions to be drawn about the composition of the sample. The results of the measurements are recorded in temperature-time diagrams, and heating or cooling curves are subsequently generated.

In contrast to dynamic thermal analysis, static thermal analysis is the second part of thermal analysis. The test specimen is kept at a constant temperature for a more extended period.

During this time, the loss of heat or water can be measured. In this way, the melting and boiling points changes are determined, and it is recorded when substances change from solid to liquid to gaseous.

Static thermal analyses can also determine the energetic, mechanical and mass change processes of an element or material. Based on this, statements can be made about volume changes and changes in the optical properties.

Which products require thermal analysis?

Thermal analysis is required for substances for which information is needed about the phase transitions from solid to liquid and possible temperature changes in the solid-state. This is of particular interest for metals, alloys and plastics. These can be products from all technical areas or the chemical industry:

- Plastics, e.g. according to DIN EN ISO 11357-1: Differential Scanning Calorimetry (DSC) or ASTM D 3418: Standard Test Method for Transition Temperature and Melting and Crystallisation Enthalpies of Polymers by Differential Scanning Calorimetry (DSC)

- Adhesives and composites, e.g. according to ISO 11409: Plastics - Phenolic resins - Determination of heat and reaction temperatures by differential scanning calorimetry or according to ASTM D 5028: Test method for the curing properties of drawing extrusion resins by thermal analysis.

- Electrical cables, e.g. according to ASTM D 4565: Standard Test Methods for Physical and Environmental Performance Characteristics of Insulation and Jackets for Telecommunications Wires and Cables.

- Inorganic and organic chemicals, e.g. according to ASTM E 474: differential thermal analysis, a method for evaluating a temperature scale

Where can I have thermal analyses carried out?

Thermal analyses according to national and international norms and standards such as DIN, EN, ISO, ASTM, IEC and CISPR, can be carried out with testxchange. With testxchange and our partner laboratories, you can find the proper thermal analysis for your products. We at testxchange and our many partner laboratories specialise in carrying out a wide range of thermal studies, among other things.

Whether you are a retailer, OEM or manufacturer of products, you can benefit from testxchange's expertise. This includes in-house project engineers who are available to advise you. Together, you select a suitable testing laboratory for the compounds and materials to be tested and carry out the tests quickly and cost-effectively.

Need thermal analysis?

If you need assistance in non-destructive testing, you can contact us directly. If you are interested in other fields of testing, we will be happy to assist you as well.